Billy Rankin, Vice President of Marketing and Public Programming

34 historic structures. 36 miles of hiking trails. 3,000 acres of natural and cultural landscape.

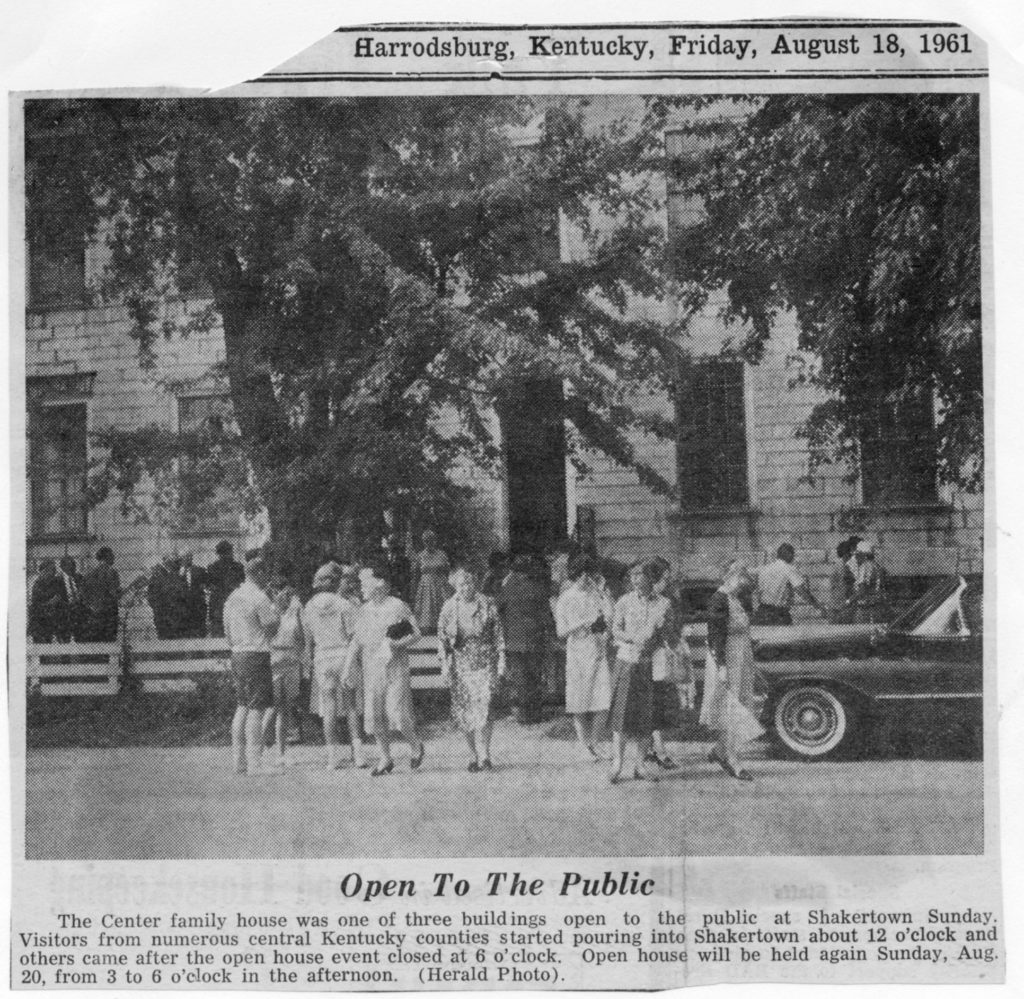

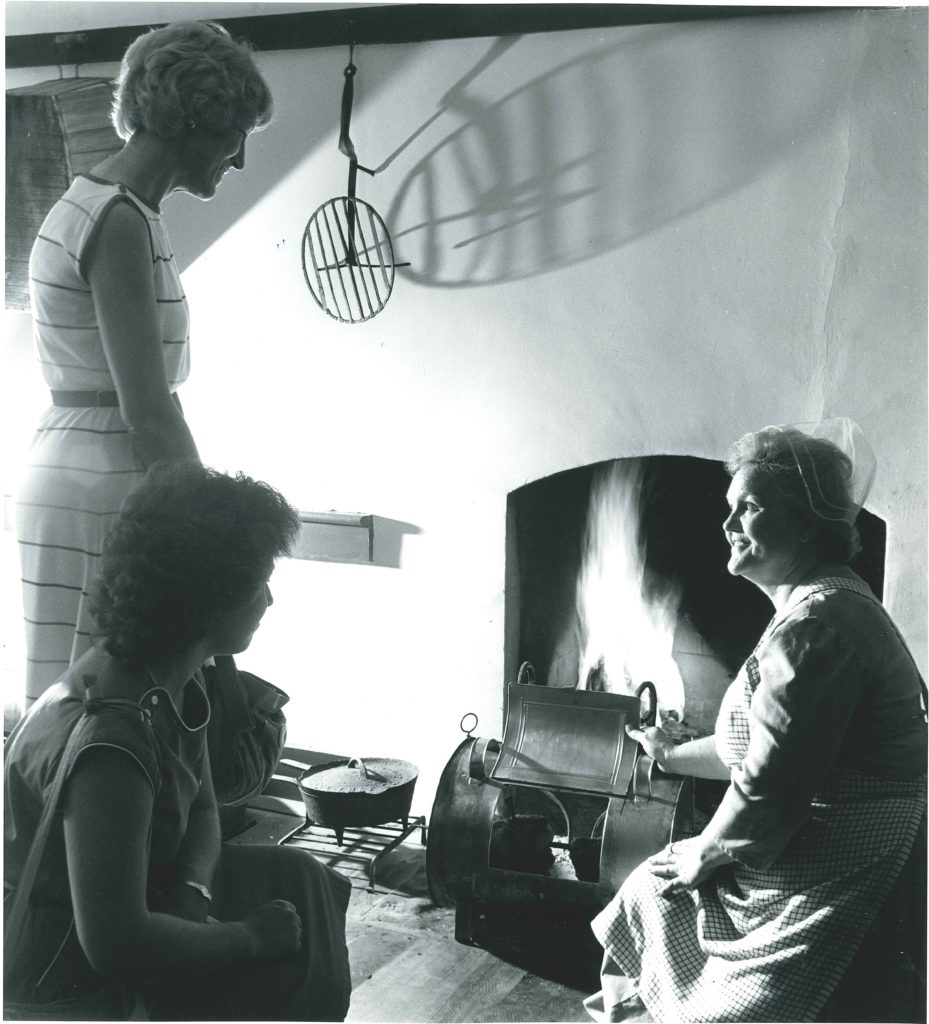

The vastness of the experience at Shaker Village of Pleasant Hill is an incredible attraction for the guests that travel from around the world to visit Kentucky’s largest National Historic Landmark. However, this grand scale can also be a challenge for guests with limited mobility.

The Challenge

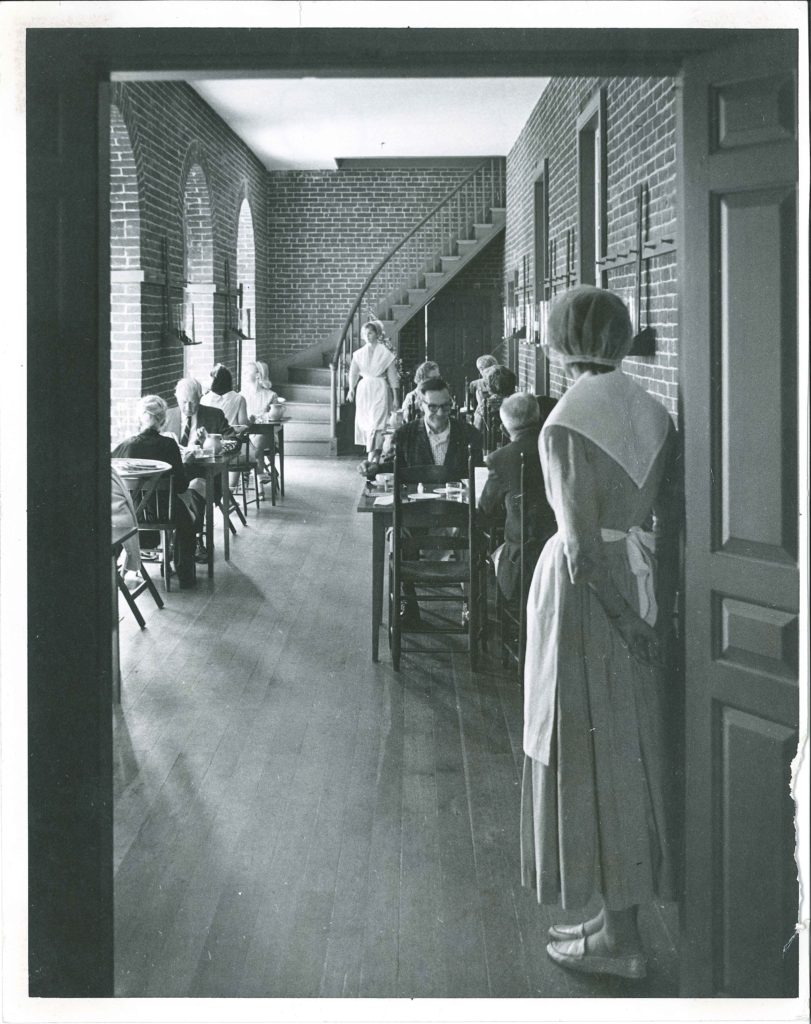

Consider the 34 historic structures at Pleasant Hill. Of these, 20 are buildings with multiple levels. While we admire the simple elegance of Shaker staircases, in the words of one recent guest, “They were great at building stairs, but not so much elevators, huh?”

Though this comment was made in jest (and the guest was probably a bit winded from the climb), providing inclusive access to spaces throughout a historic property is a very real challenge. Here are three specific areas we’re working to address:

- The historic, Shaker sidewalks that remain at Pleasant Hill are typically too narrow for wheelchairs, walkers and scooters. They can also become worn and uneven through aging, increasing the risk of slips, trips and falls.

- All of the 13 buildings that contain overnight guest rooms at the property currently require guests to navigate at least one step to access.

- Although there are educational exhibits in a dozen buildings at Shaker Village, only three of these buildings are accessible for guests using a wheelchair, and even in those, that access is restricted to only portions of the building.

So, how do we provide better access for guests with limited mobility, without damaging the aesthetic and historic integrity of this irreplaceable Village?

You Have to Start Somewhere

To be fair, there have been prior efforts toward accessibility at Shaker Village of Pleasant Hill. There are outdoor lifts to provide access into The Trustees’ Table restaurant and to meeting spaces in the West Lot Dwelling. Public restrooms at the Village are accessible as well. The difference today is that these efforts are now part of a strategic planning process, and are being emphasized as a critical part of our site plan moving forward.

The biggest limitation to implementing plans for increased accessibility at Shaker Village is, of course, funding. Fortunately, we have been able to complete several projects through the generosity of private and corporate donors.

In 2020 the Village installed 20 outdoor, educational waystations thanks to a gift from Community Trust Bank. These waystations were placed in locations that are accessible, and have made a positive impact for those guests who are unable to navigate the multiple levels of exhibits in many of the buildings.

Educational waystations can now be found along paths at the Village.

ADA accessible paths are also accompanied by accessible picnic areas.

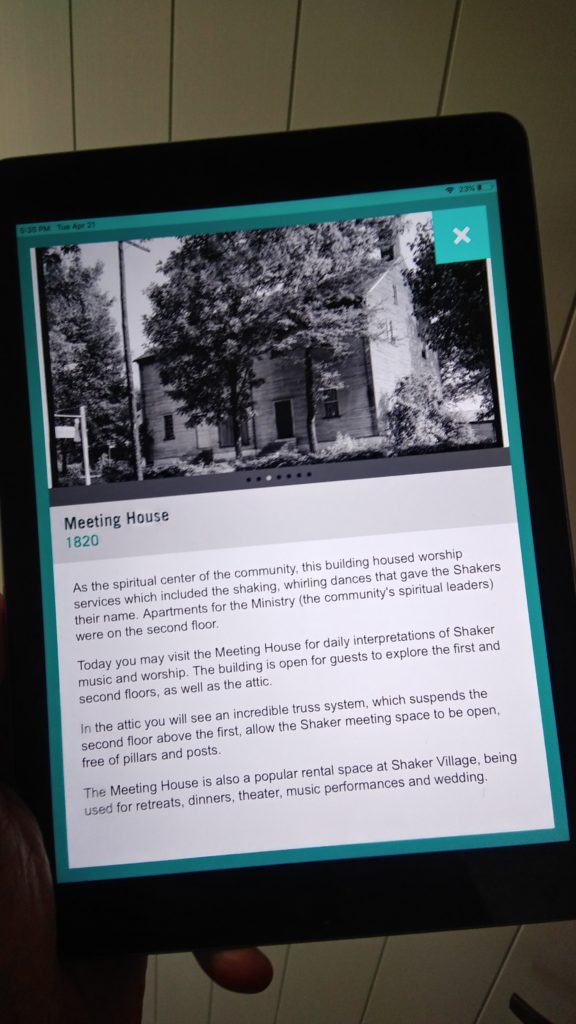

Around the same time, new pathways that meet ADA standards were created near the 1820 Meeting House and through the heirloom apple orchard. These paths are part of a larger plan to connect all the major buildings at Shaker Village with ADA compliant paths and sidewalks, and were made possible by the contribution of an individual donor.

Continuing the Progress

This month, two projects are underway that will dramatically impact accessibility at two of the most important buildings at Shaker Village.

The 1815 Carpenter’s Shop serves as the Welcome Center for the Village. While a sidewalk addition in 2017 made it possible for all guests to enter the building from one side, passing through the building and into the Village has been prohibitive for guests in wheelchairs. A new, permanent ramp is being constructed that will resolve this issue.

Once completed, this new ramp will allow all guests to pass through the Welcome Center at Shaker Village.

A new, smooth sidewalk in front of the Trustees’ Office offers safer access to the restaurant.

The 1839 Trustees’ Office, home to The Trustees’ Table restaurant, is also seeing an upgrade to improve accessibility. A new sidewalk is currently being laid, leading to the front entrance of the building and connecting to the lift on the building’s east side. By replacing a non-historic stone path that had many bumps and divots, this sidewalk is not only ADA compliant, but much safer for all of the restaurant’s patrons.

Where Do We Go From Here

In the coming years, Shaker Village of Pleasant Hill will continue to make improvements that increase access on the property for all guests.

Here are some projects to keep an eye on in the months and years to come:

- The Shaker Village App is about to go live! The App will provide an additional layer of educational information for all guests to the Village, and the multimedia content, with closed captioning, will not only provide more access for visitors with limited mobility, but also those with visual and hearing impairments.

- More ADA compliant sidewalks, pathways and ramps will be built. There are still several important areas of the Village where access needs to be improved. In the coming years you’ll see work to provide this access in the East Family area of the Village, at key buildings like the Meeting House, and around trailheads and hiking trails in The Preserve.

- Select guest rooms will be modified to meet ADA standards. This step will take a while, but we have our eyes on some spaces where building access and ADA compliance can be accomplished while maintaining the historic integrity of the buildings.

As with all undertakings of true value, there isn’t a shortcut to improving accessibility across a 3,000 acre historic property. Along the way there will be difficulties, and it will never move as quickly as we would like. However, Shaker Village should be a place where every single person can feel ‘kindly welcomed,’ and we are committed to living up to that standard.

If you would like to learn more about how you can support accessibility projects at Shaker Village of Pleasant Hill, please contact us at [email protected] or call 859.734.5411.